Inside the New Science of Hop Quality | Deep Dive

Join Craft Beer & Brewing and the experts at John I. Haas, along with Ryan Bruchey from TailGate Brewery and Jeremy Moynier from Sapporo-Stone Brewing, for a panel discussion on the evolving science of hops where sensory meets data, and innovation meets reliability.

Whether you’re a small craft brewer or managing large-scale production, you’ll come away with a clearer understanding of how modern hop science can deliver greater confidence, repeatability, and creativity in every brew.

Topics Covered

- The evolution of hop quality – from subjective selection to data-driven consistency

- How hop breeding, chemistry, and sensory analytics have changed the definition of “quality”

- Why flavor predictability matters as much as variety

- Overview of Sensory Plus™: four-step process ensuring true-to-type flavor and aroma consistency

- Democratizing hop selection: how Haas made selection accessible to all scales

- How sensory-crafted profiles work—data-driven lots categorized by flavor type

- Overview of LupoCORE™ as an enhanced T90 pellet for consistent performance

- Real-world brewer outcomes: better hop expression, no process change, greater consistency

Guests

- Ryan Bruchey, Director of Brewery Operations, TailGate Brewery

- Jeremy Moynier, Sr. Manager of Brewing Innovation & Supply Chain, Sapporo-Stone Brewing

- Jeff Dailey, Sensory Manager, Brewing Solutions Team, John I. Haas

- Josh Vigansky, Director, Products & Portfolio, Commercial Team, John I. Haas

Inside the New Science of Hop Quality

In this first part of a three-part series, experts from John I. Haas weigh in on the evolving nature of hop quality, best practices in hop selection, the challenges of year-over-year and lot-to-lot variability, and the new tools and methods available to brewers to ensure consistency from field to glass.

Historically, the phrase “high quality” in hop selection has been shorthand for a few specific, albeit superficial, factors: in-spec alpha-acid levels, low seed counts, and vibrantly green hop cones, among others. A hop that smells great in the field or the belief that it’s “supposed to be a cool variety” are often cited as markers of quality. Conversations about raw materials with hop brokers or growers once started and ended here, limited by a lack of shared understanding of what hops actually are—or could be.

But evolving consumer tastes and modern brewing techniques demand far more from hop suppliers. The brewing industry’s revised focus on flavor-forward hops and its resulting advances in analytical tools and sophisticated sensory analysis have redefined what quality actually means. Today, hops are no longer viewed as simply an essential ingredient; they are sensory instruments whose chemistry, condition, and consistency directly shape a beer’s identity.

At John I. Haas, we have evolved alongside the industry. Across our farms, labs, and brewhouses, quality has become a multidimensional concept—one that blends breeding, cultivation, chemistry, sensory, and how we approach customer selection in ways that didn’t exist a generation ago. In a three-part series, we’ll explore some of the tools and methods brewers should be using today to close the loop on hop quality, starting with redefining their approach to selection.

Drivers of Hop and Harvest Quality

Hop quality can’t be summed up in a single metric—it exists along a spectrum of interdependent factors:

- Chemical composition—Alpha and beta acids, total oil, and key fractions such as myrcene, humulene, and linalool

- Sensory profile—The balance between varietal fingerprint and seasonal nuance

- Physical integrity—Cone structure, moisture, and appearance post-drying and baling

- Consistency and stability—The ability of a lot to perform as expected across multiple brews

What makes this tricky is that these parameters don’t always align. A hop lot with a textbook oil profile can still disappoint in the glass if harvest timing or drying went off target. Likewise, a hop that smells underwhelming raw can reveal exceptional synergy in beer.

Harvest Windows: Where Quality Begins

The harvest window—the period when chemistry, sensory, and yield align—is one of the biggest determinants of hop quality. For some varieties, that window is widening; for others, climate and agronomic pressures are compressing it.

Haas Sensory Panels have observed that even a seemingly minor shift in harvest timing can alter citrus or tropical profiles by more than 30 percent in sensory intensity. As a result, precision harvest management has become as critical as breeding itself.

However, Haas Sensory Panels have also observed that the concept of a single harvest window is outdated. Because of the multidimensional nature of the influences on quality—location, microclimate, soil quality, viral status, rootstock age, agronomic and fertility practices, and even “timing”—we’ve observed clear, consistent trends in sensory profiles that don’t align neatly with “early,” “middle,” and “late.” For example, Citra picked on the same day in Moxee and Wapato can be wildly different, even though they’re managed by the same farm and grown only 10 miles apart.

Suppliers and brewers can leverage this knowledge whether they’re using traditional selection or not.

The Changing Nature of Selection

For large global brewers, hop selection is often a data-driven exercise supported by analytics, large-scale production demands, and long-term supplier agreements. For craft brewers, it’s often a once-a-year sensory sprint through dozens of lots in Yakima or Hallertau.

Each approach reflects the same goal—a reliable sensory outcome—but operates under vastly different constraints. Smaller brewers may select by nose and intuition; larger ones rely on metadata and multiyear lot-performance models.

Best Practices in Selection

No matter the scale, three best practices hold true:

- Conduct side-by-side sensory evaluations—Always assess multiple lots of the same variety together to expose differences in freshness, expression, and drying character.

- Use Certificates of Analysis (CoAs) as context, not verdicts—Analytical data provide valuable clues but never tell the full story.

- Engage the supply chain early—The best results come from year-round communication with growers and suppliers, not just harvest-week selection.

Variability and Data Challenges

Even within a single variety, no two years are identical. Variations in temperature, drought stress, and pest load can shift oil balance and alter aroma character. Growers must often balance yield and quality, adjusting irrigation and drying practices in real time. These small changes ripple down to the sensory experience, turning “bright tropical” one year into “green herbal” the next.

In addition, brewers often underestimate how much variance exists across lots, even within a single variety. Two bales from the same field can smell and taste distinctly different. That’s not necessarily a failure of process; it’s the nature of an agricultural product.

The challenge isn’t just managing the variability—it’s tracking it. Without robust metadata—field data, drying temperature logs, analytical history—it’s almost impossible to correlate sensory shifts with root causes.

Using Data to Manage Chaos

Progressive brewers and suppliers are beginning to classify lots using clustered sensory and analytical profiles—for example, grouping Citra lots as citrus-forward, floral-forward, or sweet fruit–leaning. Tracking these clusters across harvest years allows teams to maintain brand sensory consistency even as raw materials fluctuate.

Sensory and Selection Teams: Training and Calibration

Human bias—often invisible but powerful—can strongly influence hop selection. Fatigue, expectation, and previous experience can all skew sensory evaluation.

At Haas, our teams focus on structured calibration, cross referencing panel impressions with chemical markers and proven sensory lexicons. Breweries, regardless of size, can benefit from similar internal training: establishing shared descriptors, using blind trials, and revisiting calibration throughout the season.

Where Traditional Selection Hits Its Limits

Even with the best-trained noses and the right data in hand, traditional selection has limits. Certain chemical divergences are simply imperceptible, or uncontrollable, by sensory means alone.

As hop breeding advances and weather volatility increase, those unseen differences can have outsized impacts on beer flavor. The industry is headed toward augmented, data-integrated selection systems that combine human expertise with analytical precision.

We’ll explore the Haas Next Gen approach in Part 2 of this series.

Supplier Practices and Quality Expectations

Today’s brewers should expect—nay, demand—transparency from their suppliers. That means:

- Full traceability from farm block to bale to pellet

- CoAs enriched with metadata, including harvest date, drying parameters, and sensory class

- Consistent QC protocols validated across facilities and regions

Modern suppliers aren’t just raw-material vendors; they’re stability partners, providing data and guidance that empower brewers to hit their flavor targets every time.

Defining the Path Forward

Raw-material quality is no longer about what a hop is—it’s about what it does in beer and how reliably it does it. For brewers and suppliers alike, the next era of hop quality will be defined by integration, not just intuition: chemistry with sensory, instinct with data, and farm-level insight with proven brewery performance.

As we’ll explore in Part 2, new tools and methodologies such as the Haas’ Sensory Plus™ engineering process and the new Next Gen Selection platform are designed to make that integration scalable, objective, and repeatable.

In a world where quality keeps evolving, the real challenge isn’t finding the right hop for your beer profile; it’s finding the hop solution that best fits your beer, every time.

Unlocking Reliability With New Hop Solutions for Every Brewer

Discover how John I. Haas is transforming sensory science from instinct to engineered precision—creating shared language, repeatable flavor outcomes, and brewer-driven trust through Sensory Plus™, Next Gen Selection, and the Lupo Series™ of engineered hop pellets.

“Inside the New Science of Hop Quality” explored how hop selection has evolved from instinct to data-driven precision. Here we look at what happens next—because selection alone can’t close the year-over-year gaps that every brewer faces.

No matter how skilled the panel or how perfect the harvest, sensory drift happens. Climate variability, crop stress, and process nuances can all nudge a hop’s aromatic fingerprint in unexpected directions over time. Traditionally, the industry’s answer to that challenge was to rely on expert authority: a few seasoned noses trusted to “find” the best quality hops based on instinct and experience.

But as brewer expectations, beer styles, and sensory science have matured, so has the realization that authority alone isn’t enough.

The Limits of Relying on the Experts

In the old model, sensory evaluation often meant trusting a specialist behind closed doors. After hops were assessed and lots chosen, brewers received a promise that they were getting the “good stuff” and went off to brew their beers.

That approach worked for many until brewers began analyzing outcomes more closely. As more breweries developed their own sensory programs, they noticed discrepancies between supplier assessments and what showed up in the glass—revealing gaps not in quality, but in perception.

As we discussed in “Inside the New Science of Hop Quality,” quality can mean different things to different people. What one panel might describe as “bright and tropical,” another might call “sweet fruit” or “candy-like.” Without shared reference points or repeatable systems, communication can break down and consistency can suffer.

Building a Shared Sensory Language

Before sensory consistency could be engineered, it first had to be understood. Brewers began taking part in collaborative programs that captured their own definitions of hop quality, correlating how “perfect Citra” or “ideal Mosaic” performed not only in raw form, but also in beer.

From those exercises came shared reference points—calibrated descriptors, sensory anchors, and lexicons—that gave evaluators a common language. Terms such as “resinous,” “citrus,” or “stone fruit” now carried measurable meaning, connecting sensory perception with analytical data. This foundation let brewers and suppliers discuss hops in the same terms and with the same intent.

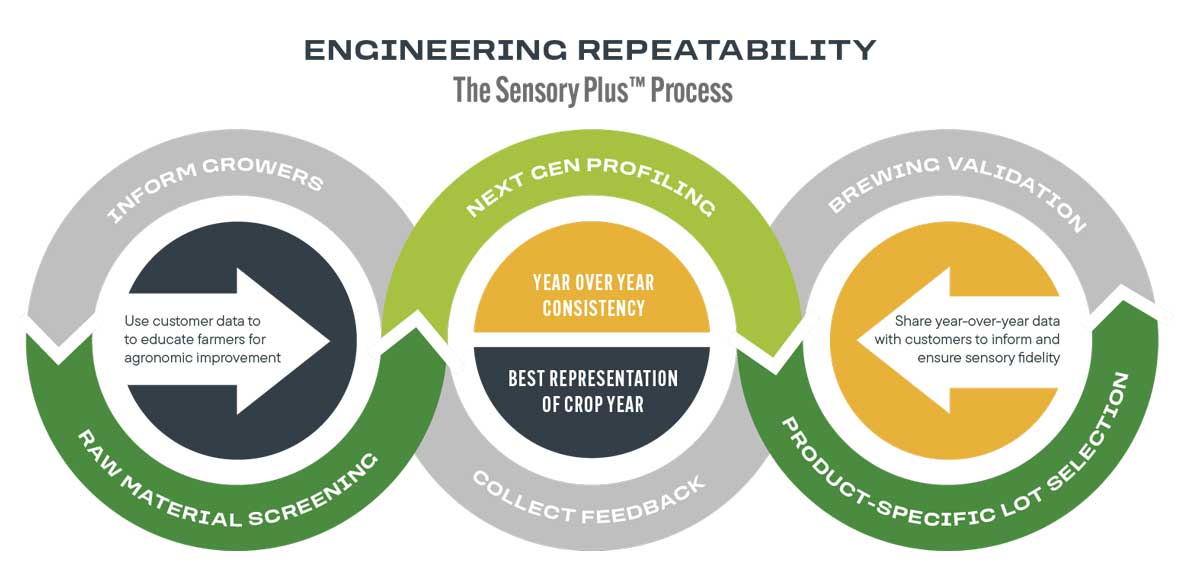

Engineering Repeatability: The Sensory Plus Story

As that shared language matured, Haas asked a bigger question: Can sensory be engineered for consistency?

The answer became Sensory Plus™, a proprietary framework that integrates sensory evaluation, chemistry, and process validation into a single, repeatable system.

Multistage Screening

Hops are evaluated at multiple points—from raw cone to pellet—to ensure that their sensory fingerprint remains aligned throughout processing.

Sensory Profiling and Segmentation

Hop lots are organized into clusters that represent distinct aroma families such as citrus-forward, floral-forward, or sweet fruit–leaning. Each cluster is supported by analytical data, bridging sensory impressions with measurable chemistry.

Validation and Feedback

Once classified, hop lots undergo repeat evaluations and cross-checks against sensory and chemical targets. Feedback from brewers closes the loop, confirming that what’s observed in the lab performs as expected in the brewhouse and the pint glass.

Sensory Plus translates sensory impressions into reproducible data, helping preserve hop identity despite natural variability from season to season.

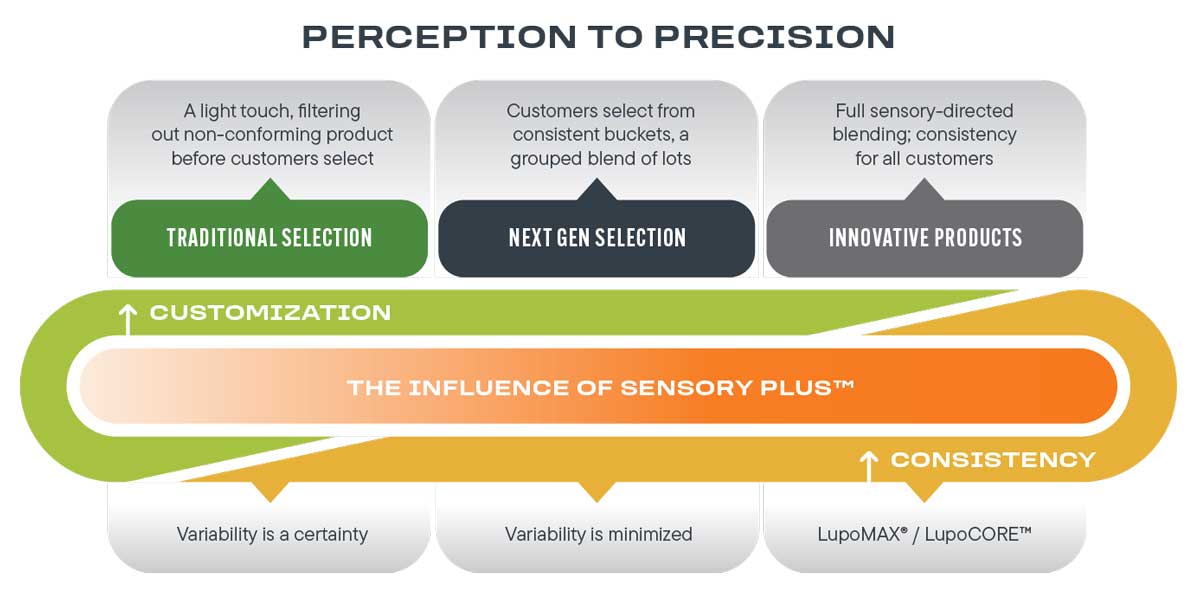

Expanding Access to True Hop Selection through Sensory Plus

For many small and midsized brewers, traditional hop selection has often been out of reach, limited by scale, scheduling, or purchasing requirements that favor larger producers. The Next Gen Selection program makes that experience accessible to breweries of every size. With low minimum commitments and flexible purchasing options, brewers can now take part directly in harvest selection and choose lots that best match their flavor and aroma targets.

Next Gen uses Sensory Plus profiles to organize hop lots into consistent, true-to-type sensory groupings. Brewers evaluate these lots during harvest and select the expression that best fits their beer portfolio. The program gives smaller breweries greater control over ingredient quality and the confidence that their chosen profiles will remain consistent from one crop year to the next.

Integrating Sensory Plus with Lupo Series Hop Pellets

Consistency doesn’t end at selection; it extends into how hops are processed and delivered. The Sensory Plus™ framework is applied throughout hop development and production to ensure that finished pellets retain their intended sensory targets batch after batch and crop after crop.

Every lot used in LupoCORE® and LupoMAX® is screened and blended according to defined sensory and chemical parameters, producing hop products that maintain true-to-type aroma and flavor performance regardless of variety or growing season. The result is cleaner, more concentrated hop expression with less vegetative material and improved brewing efficiency—helping brewers achieve reliable flavor outcomes and consistent beer profiles over time.

Scaling Sensory Globally

The expansion of sensory-based quality systems is not limited to the Pacific Northwest. Collaboration with international partners has shown how these principles can elevate hop quality worldwide. A recent example comes from Haas’s work with the Hop Products Australia (HPA) team and its flagship variety, Galaxy®. Once facing challenges with consistency and perception, the HPA team began implementing sensory-guided standards and traceability protocols modeled after those refined in Yakima. By documenting and analyzing hop characteristics across multiple harvests, the teams identified and reduced sources of nonconforming material, leading to measurable gains in aroma clarity and lot reliability.

The partnership evolved through several years of shared calibration, process improvements, and targeted agronomic adjustments. Each step, from recording observations and applying sensory thresholds to tracing inputs through the supply chain, improved Galaxy’s overall performance. The results were clear: cleaner flavor expression, greater batch-to-batch consistency, and growing brewer confidence in one of Australia’s most distinctive hop varieties.

By 2025, these efforts culminated in the launch of Hop Central, HPA’s new processing facility built to support modern sensory-driven production. The integration of standardized sensory evaluation marked the culmination of a multiyear effort to align harvest practices, processing systems, and product outcomes across hemispheres. This shared adoption of sensory-based principles continues to grow globally, proving that consistent flavor and quality can be achieved wherever hops are cultivated.

Practical Tools for Consistency

Whether you’re a regional craft brewery or a global producer, modern sensory science can be applied at any scale. Here are a few ways to strengthen consistency and flavor reliability in your brewing process:

- Build internal calibration. Establish shared descriptors and train sensory panels regularly to align language and expectation.

- Close the feedback loop. Compare finished beer outcomes with supplier sensory data each season to refine consistency.

- Leverage engineered products. Use Sensory Plus-based hop products such as LupoCORE™ and LupoMAX® for consistent brewhouse performance.

- Adopt Next Gen Selection. Use Sensory Plus hop profiles to align raw hop character with desired beer outcomes, ensuring flavor reliability from lot to lot and crop to crop.

Sensory as a System, Not an Opinion

The next frontier of hop quality isn’t about discovering the “best” hop; it’s about achieving repeatability and precision in how hops perform. By combining sensory data with chemistry and brewing validation, the industry is moving toward a more transparent, measurable standard for hop quality.

That shift—from intuition to integration—empowers brewers to build consistency into their recipes and flavor expectations year after year. In this new era of sensory science, quality is no longer a matter of opinion. It’s a system that connects the field, the lab, and the glass in one continuous cycle of reliability.

Continue the conversation about hop quality. Join the Haas team alongside industry leaders for a live panel discussion on the evolving science of hops, where sensory meets data and innovation meets peace of mind.