“Inside the New Science of Hop Quality” explored how hop selection has evolved from instinct to data-driven precision. Here we look at what happens next—because selection alone can’t close the year-over-year gaps that every brewer faces.

No matter how skilled the panel or how perfect the harvest, sensory drift happens. Climate variability, crop stress, and process nuances can all nudge a hop’s aromatic fingerprint in unexpected directions over time. Traditionally, the industry’s answer to that challenge was to rely on expert authority: a few seasoned noses trusted to “find” the best quality hops based on instinct and experience.

But as brewer expectations, beer styles, and sensory science have matured, so has the realization that authority alone isn’t enough.

The Limits of Relying on the Experts

In the old model, sensory evaluation often meant trusting a specialist behind closed doors. After hops were assessed and lots chosen, brewers received a promise that they were getting the “good stuff” and went off to brew their beers.

That approach worked for many until brewers began analyzing outcomes more closely. As more breweries developed their own sensory programs, they noticed discrepancies between supplier assessments and what showed up in the glass—revealing gaps not in quality, but in perception.

As we discussed in “Inside the New Science of Hop Quality,” quality can mean different things to different people. What one panel might describe as “bright and tropical,” another might call “sweet fruit” or “candy-like.” Without shared reference points or repeatable systems, communication can break down and consistency can suffer.

Building a Shared Sensory Language

Before sensory consistency could be engineered, it first had to be understood. Brewers began taking part in collaborative programs that captured their own definitions of hop quality, correlating how “perfect Citra” or “ideal Mosaic” performed not only in raw form, but also in beer.

From those exercises came shared reference points—calibrated descriptors, sensory anchors, and lexicons—that gave evaluators a common language. Terms such as “resinous,” “citrus,” or “stone fruit” now carried measurable meaning, connecting sensory perception with analytical data. This foundation let brewers and suppliers discuss hops in the same terms and with the same intent.

Engineering Repeatability: The Sensory Plus Story

As that shared language matured, Haas asked a bigger question: Can sensory be engineered for consistency?

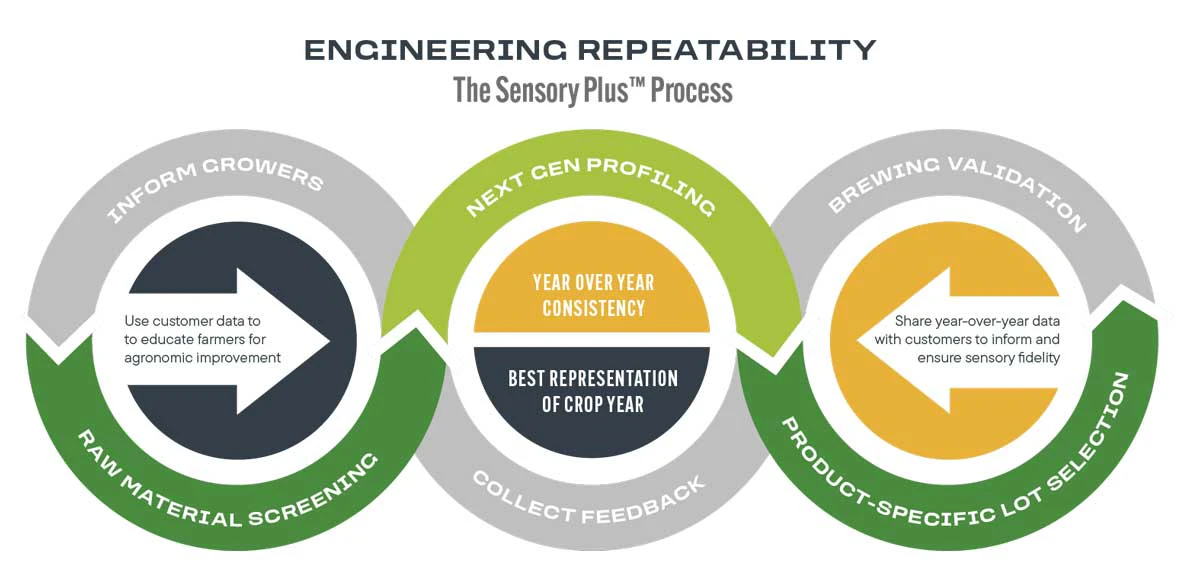

The answer became Sensory Plus™, a proprietary framework that integrates sensory evaluation, chemistry, and process validation into a single, repeatable system.

Multistage Screening

Hops are evaluated at multiple points—from raw cone to pellet—to ensure that their sensory fingerprint remains aligned throughout processing.

Sensory Profiling and Segmentation

Hop lots are organized into clusters that represent distinct aroma families such as citrus-forward, floral-forward, or sweet fruit–leaning. Each cluster is supported by analytical data, bridging sensory impressions with measurable chemistry.

Validation and Feedback

Once classified, hop lots undergo repeat evaluations and cross-checks against sensory and chemical targets. Feedback from brewers closes the loop, confirming that what’s observed in the lab performs as expected in the brewhouse and the pint glass.

Sensory Plus translates sensory impressions into reproducible data, helping preserve hop identity despite natural variability from season to season.

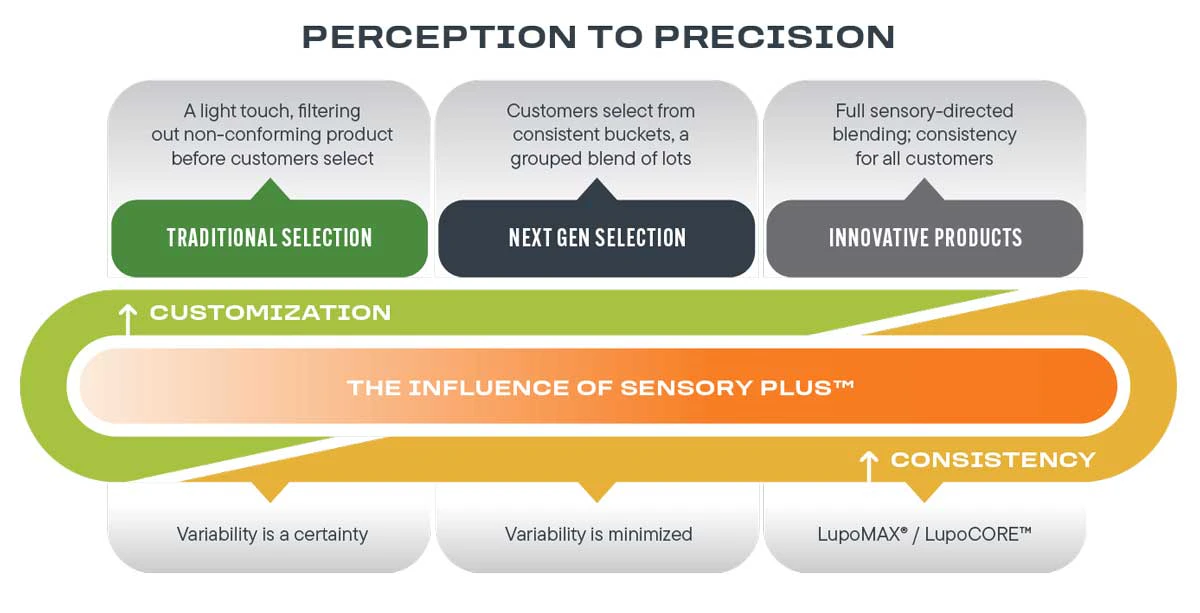

Expanding Access to True Hop Selection through Sensory Plus

For many small and midsized brewers, traditional hop selection has often been out of reach, limited by scale, scheduling, or purchasing requirements that favor larger producers. The Next Gen Selection program makes that experience accessible to breweries of every size. With low minimum commitments and flexible purchasing options, brewers can now take part directly in harvest selection and choose lots that best match their flavor and aroma targets.

Next Gen uses Sensory Plus profiles to organize hop lots into consistent, true-to-type sensory groupings. Brewers evaluate these lots during harvest and select the expression that best fits their beer portfolio. The program gives smaller breweries greater control over ingredient quality and the confidence that their chosen profiles will remain consistent from one crop year to the next.

Integrating Sensory Plus with Lupo Series Hop Pellets

Consistency doesn’t end at selection; it extends into how hops are processed and delivered. The Sensory Plus™ framework is applied throughout hop development and production to ensure that finished pellets retain their intended sensory targets batch after batch and crop after crop.

Every lot used in LupoCORE® and LupoMAX® is screened and blended according to defined sensory and chemical parameters, producing hop products that maintain true-to-type aroma and flavor performance regardless of variety or growing season. The result is cleaner, more concentrated hop expression with less vegetative material and improved brewing efficiency—helping brewers achieve reliable flavor outcomes and consistent beer profiles over time.

Scaling Sensory Globally

The expansion of sensory-based quality systems is not limited to the Pacific Northwest. Collaboration with international partners has shown how these principles can elevate hop quality worldwide. A recent example comes from Haas’s work with the Hop Products Australia (HPA) team and its flagship variety, Galaxy®. Once facing challenges with consistency and perception, the HPA team began implementing sensory-guided standards and traceability protocols modeled after those refined in Yakima. By documenting and analyzing hop characteristics across multiple harvests, the teams identified and reduced sources of nonconforming material, leading to measurable gains in aroma clarity and lot reliability.

The partnership evolved through several years of shared calibration, process improvements, and targeted agronomic adjustments. Each step, from recording observations and applying sensory thresholds to tracing inputs through the supply chain, improved Galaxy’s overall performance. The results were clear: cleaner flavor expression, greater batch-to-batch consistency, and growing brewer confidence in one of Australia’s most distinctive hop varieties.

By 2025, these efforts culminated in the launch of Hop Central, HPA’s new processing facility built to support modern sensory-driven production. The integration of standardized sensory evaluation marked the culmination of a multiyear effort to align harvest practices, processing systems, and product outcomes across hemispheres. This shared adoption of sensory-based principles continues to grow globally, proving that consistent flavor and quality can be achieved wherever hops are cultivated.

Practical Tools for Consistency

Whether you’re a regional craft brewery or a global producer, modern sensory science can be applied at any scale. Here are a few ways to strengthen consistency and flavor reliability in your brewing process:

- Build internal calibration. Establish shared descriptors and train sensory panels regularly to align language and expectation.

- Close the feedback loop. Compare finished beer outcomes with supplier sensory data each season to refine consistency.

- Leverage engineered products. Use Sensory Plus-based hop products such as LupoCORE™ and LupoMAX® for consistent brewhouse performance.

- Adopt Next Gen Selection. Use Sensory Plus hop profiles to align raw hop character with desired beer outcomes, ensuring flavor reliability from lot to lot and crop to crop.

Sensory as a System, Not an Opinion

The next frontier of hop quality isn’t about discovering the “best” hop; it’s about achieving repeatability and precision in how hops perform. By combining sensory data with chemistry and brewing validation, the industry is moving toward a more transparent, measurable standard for hop quality.

That shift—from intuition to integration—empowers brewers to build consistency into their recipes and flavor expectations year after year. In this new era of sensory science, quality is no longer a matter of opinion. It’s a system that connects the field, the lab, and the glass in one continuous cycle of reliability.

Continue the conversation about hop quality. Join the Haas team alongside industry leaders for a live panel discussion on the evolving science of hops, where sensory meets data and innovation meets peace of mind.