Starting a craft brewery takes confidence and grit … but scaling one? That’s a whole different challenge. As demand grows, so do the pressures: tighter margins, higher labor costs, and the need to boost daily output without burning out your team.

That’s when many breweries realize that it’s not just about brewing more beer but about packaging smarter. Upgrading from manual to automated processes can make a massive difference in efficiency, consistency, and profitability.

If your team is still applying carriers by hand, it might be time to rethink your setup. Here, we explore the benefits of automating your packaging line, how to spot production bottlenecks, and why replacing your manual applicator can be a game-changer for growth.

The Bottleneck Behind the Boom

One of the biggest challenges facing fast-growing craft breweries is keeping up with demand. As orders increase, production bottlenecks can quickly surface, especially if your packaging line still relies on manual labor.

Manual application may have worked when your operation was smaller, but as your output grows, manual application can become a serious drag on efficiency, profitability, and employee well-being. That’s why more breweries are turning to automation to streamline production and scale smarter.

What may seem like a small piece of the line can actually create major slowdowns, especially when throughput can’t keep pace with production. If your applicator is falling behind, it could be holding back your entire operation.

Here are a few clear signs it’s time to upgrade:

- Your filler’s speed is a competitive advantage—unless you’re slowing it down: If you’re running at 70–80+ cans per minute but still applying carriers by hand, you’re not just wasting production time. You’re risking delays that could keep you from meeting demand.

- Misaligned carriers or missed cans: Manual can-carrier application is inherently more prone to mistakes at speed—like misaligned carriers or missed cans during the application process. These errors don’t just lead to rework; they directly interrupt your line’s flow and cost valuable production time.

- Your team is feeling the strain: Free them from repetitive tasks and reallocate their skills to higher-value activities within your operation, instead of incurring higher overtime costs or risking burnout.

The bottom line? Upgrading to an automated can-carrier applicator isn’t just about faster production; it’s about transforming your operational efficiency. You’ll unlock significant improvements in line speed, consisent reliability, and strategic labor reallocation, giving your brewery the sustainable edge it needs to meet demand and grow.

Meet the VPA-80: Compact, Fast, Cost-Effective, and Built for Breweries Like Yours

If manual carrier application is slowing your packaging, it may be time to upgrade to a modern, automated solution.

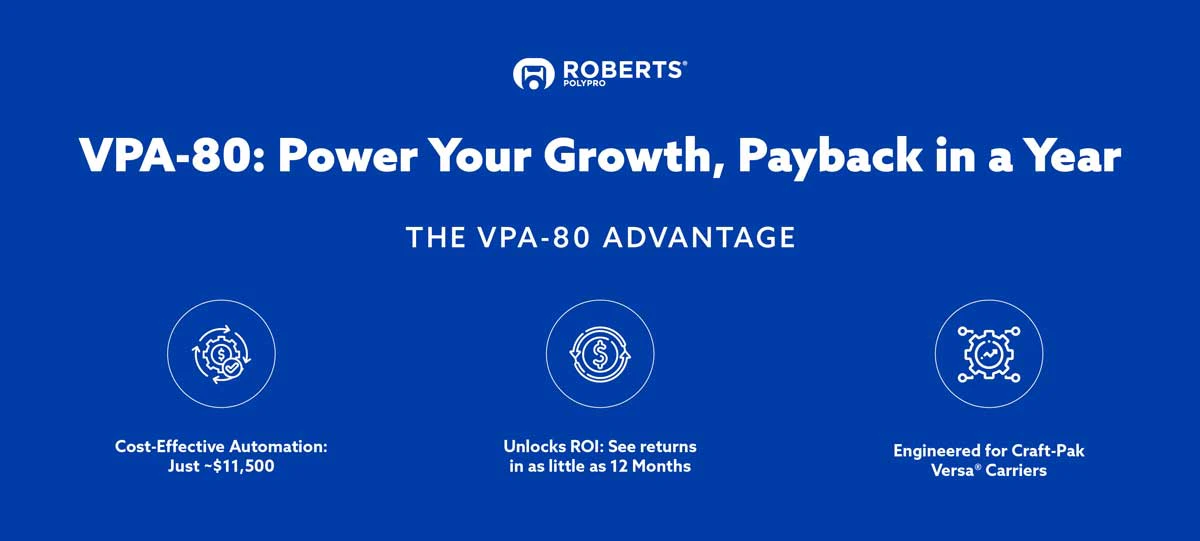

Ready to tackle your toughest canning-line challenges? The VPA-80 from Roberts PolyPro offers the automation your growing brewery needs to access new levels of efficiency and production. Here’s why it’s a game-changer:

- Built for Craft‑Pak® Versa: The VPA-80 applies Roberts PolyPro’s 100 percent biodegradable Craft-Pak® Versa can carriers, using up to 50 percent less plastic and costing up to 25 percent less than competitor handles.

- Increased Throughput: The VPA‑80 delivers speeds up to 80 CPM, offering a smart, efficient replacement for manual application.

- Less Downtime, More Flexibility: Compatible with 12, 16, and 19.2 oz cans, the VPA-80 requires no change parts to switch between four- and six-pack carriers, just a simple height adjustment for can size.

- Smart Automation, Fewer Hands: With the VPA-80 handling precise carrier application, your single operator can focus solely on loading carriers and efficient pack-out, significantly reducing labor demands and keeping your line moving consistently.

- Configurable to Your Layout: Compact and reliable, the VPA-80 fits seamlessly into any operation with a small footprint and offers 90° left or right inline options to match your setup.

Why Now Might Be the Best Time to Upgrade

Maybe you’re considering an automated can-carrier applicator for your growing brewery, but does it really need to happen right now?

The short answer: yes. Waiting could actually cost you more in the long run.

Manual application delays, labor inefficiencies, and lost output add up quickly, sometimes to tens of thousands of dollars per year. And if you’re running low on inventory because of production slowdowns, the cost of missed sales can be just as painful. In 2021, for example, consumer packaged goods (CPG) retailers lost out on 7.4 percent in sales because of stockouts.

Upgrading to a modern applicator such as the VPA‑80 isn’t just about fixing problems. It’s a step toward faster, smarter production. And with a price tag around $11,500, it’s a cost-effective investment compared to other upgrades.

Plus, from a competitive standpoint, efficient and reliable packaging gives your brewery a leg up as you expand into new markets.

Is It Time to Rethink Your Packaging Line?

The only way to know is to ask yourself the following questions:

- Are your labor costs rising?

- Are you struggling to meet demand?

- Is manual application slowing you down?

- Do you want to improve your sustainability practices?

If you answered “yes” to any of the above, it may be time to consider an upgrade.

Scaling smarter doesn’t have to mean hiring more people or compromising on quality. With the right equipment, you can boost production, reduce labor strain, and see a strong return on investment—all without breaking the bank.

Whether you’re interested in a new applicator, sustainable can carriers or both, the team at Roberts PolyPro can guide you toward a packaging solution that meets your goals for efficiency, scalability, and sustainability.

Connect with Roberts PolyPro today to see how you can scale your brewery with confidence.