Everyone told you how easy kegging is, how much time you’ll save, and how rewarding it is to pour a glass of beer at your own home bar. You even built your own kegerator, complete with stainless faucets and a shiny draft tower, the whole nine yards.

So you invite your friends over to break it in, and with great fanfare and excitement, you draw your first pint of . . . foam.

No big deal, the first pint is always a little sudsy. So you pull a second. And then a third. Now you’re starting to worry. As pint after pint of foamy but precious homebrew goes down the drain, you wonder what went wrong.

Stop wasting beer! As they say in the yogurt commercials, your system may be out of balance. A balanced draft system is crucial to pouring foam-free beer.

Under Pressure

The problem with dissolved carbon dioxide is that it doesn’t like to stay dissolved. You intuitively know this from the pleasant hissing noise you hear when you open a bottle. If beer pours out of a faucet too quickly, carbon dioxide readily comes out of solution, and you end up with nothing but foam. The trouble is that the correct dispensing pressure needs to satisfy competing requirements:

- Carbonate your beer.

- Overcome the flow resistance in your draft system.

To satisfy both of these requirements with the same pressure, you need to supply a flow resistance that is only slightly exceeded by the carbonation pressure. Resistance in the system comes from two main sources:

- Gravity: A certain amount of pressure is needed to push beer up through a draft tower.

- Line resistance: Friction from the beverage line tends to slow down the beer as it travels from keg to faucet.

The contribution from gravity is pretty much a constant once you have your kegerator assembled. It depends only on the height between the keg and the faucet.

Line resistance, on the other hand, is easily changed. Use longer lines for more resistance and shorter lines for less. Many homebrew draft systems come standard with five foot beverage lines, but these are frequently too short for tower-based kegerators.

Do the Math

Figuring out the proper line length requires just a bit of math, but you only need to do it once as long as you don’t change anything.

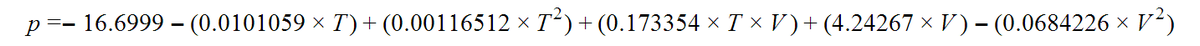

First calculate the pressure (p, in pounds per square inch) needed to properly carbonate your beer to a certain carbonation level (V, in volumes of carbon dioxide) at the temperature (T in degrees Fahrenheit) at which you’ll serve it.

This is your serving pressure. Now you need to figure out how much resistance you need to overcome it. Initially, just make the resistance equal to the serving pressure (those who live at high elevations should add an additional 0.5 pound per square inch for every 1,000 feet above sea level).

Gravity contributes about 0.5 pound per square inch (psi) of resistance per foot of height. So if your faucet sits a foot higher than the keg, you can subtract 0.5 psi from the needed resistance since gravity is taking care of that for you. If, on the other hand, the faucet sits a foot below the keg, you’ll need to add 0.5 psi to the resistance since gravity will accelerate the beer through the line as it flows to the faucet.

After you’ve accounted for gravity, the remaining resistance is the required line resistance. This will depend upon the type of line you’re using, but values for common vinyl lines of various inner diameters (ID) are as follows (Source: Draft Beer Quality Manual, Brewers Association):

- 3/16" ID: 3.0 psi per foot

- 1/4" ID: 0.85 psi per foot

- 5/16" ID: 0.40 psi per foot

- 3/8" ID: 0.20 psi per foot

- 1/2" ID: 0.025 psi per foot

Take the required line resistance and divide it by the resistance value of your tubing to obtain line length, in feet, needed to overcome the serving pressure.

An Example

Let's run through an example to demonstrate how it's done. I'm using a real calculation based on my home kegerator. Let's say I keep my kegerator at 40°F (4°C) and that I would like to serve an American IPA, which is usually carbonated to between 2 and 2.5 volumes of CO2. I happen to like mine on the fizzy side, so I’m aiming for 2.5 volumes. Our first order of business is to calculate the serving pressure that will achieve 2.5 volumes of CO2 at a temperature of 40°F.

Plugging T=40 and V=2.5 into the equation above, I calculate that the pressure, p, needs to be 12.27 psi.

I live in Fort Collins, Colorado, which is about 5,000 feet above sea level, so I need to adjust that number to account for the lower atmospheric pressure up here. You need to add 0.5 psi to your serving pressure for every 1,000 feet of elevation, which means I’ll add 2.5 psi, for a final serving pressure of 14.77 psi.

I can now place my keg of American IPA in the 40°F fridge and hook it up to the gas at 14.77 psi (12.27 psi if I lived at sea level), and after a week or two, it will be perfectly carbonated. Now we have to consider gravity and line length to make sure there is enough resistance to sufficiently slow that carbonated IPA by the time it reaches my faucet.

In theory, you want to measure the height between the fill level in the keg and the faucet. But since the fill level changes as you drain the keg, a good compromise is to simply measure from the center of the keg. My faucet sits about 2.5 feet above the center of the keg. For every foot above the keg, we get 0.5 psi of resistance from gravity, which means the 2.5 foot rise will supply 1.25 psi of gravity resistance.

The remaining resistance we need to supply, then, is 14.77 psi − 1.25 psi = 13.52 psi.

This 13.52 psi has to be managed using beer lines. We’ll use commonly available 3/16" ID vinyl lines, which provide 3 psi of resistance per foot.

So, the total line length is 13.52 psi ÷ 3 psi per foot = 4.5 feet

A 4.5-foot beverage line should be sufficient for a nice, foam-free pour in this example.

A Balanced Life

The math is, of course, all theory. In practice, you may want to select a line length that’s slightly longer and then trim it back if you find that your beer is pouring too slowly. It’s much easier to trim a line that’s too long than it is to remove a short line and replace it with a longer one.

Once you’ve found the proper length for your beer lines, you’ll have a system that will happily serve you over and over again. And you will have discovered the true joys of foam-free draft beer at home.